Showing posts with label sensor. Show all posts

Showing posts with label sensor. Show all posts

Wednesday, November 19, 2014

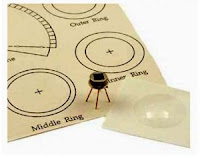

Line Follower Robot Sensor Concept

Line Follower Robot Sensor Concept - Sensor line detector is used in line follower robot is usually based on the principle of light reflectionto distinguish the line with the background color. In the dark color of the light absorption is greater than that of white light reflected to the sensor becomes smaller.

Position sensor to track the trajectory and the example circuit.

| Line Follower Robot Sensor Concept |

Light used for the introduction of the line is usually visible light and infra-red. Sensors for visible light are commonly used are LDR (Light Depending Resistance), while for the infrared light is atransistor and photo diode (photodiode). Sensors placed at the bottom of the frame to hang the robot, so that its position can be located just above the track to be read.

Tuesday, November 18, 2014

Color Sensor with TSC230

Color Sensor TCS230 color sensor is a chip that works with the converting acceptance of a certain color of light emitted into the shape of frequency. TCS230 Color Sensor composed dri two main parts, namely a light-receiving section arranged in an array photodioda and Chaya koncerter this part to the frequency. Basically the TCS230 Color Sensor is a light sensor which is equipped with light filters for RGB primary color (Red-Green-Blue) and light sensor without the filter with scale 8 bits for each of this part of the sensor.

|

| TSC230 Color Sensor |

|

| Pin Diagram |

Photodiode the TCS230 Color Sensor arrays arranged in 8 × 8 with the internal configuration of the photodiode. 16 photodiode for the light sensor with a red light filter. 16 photodiode for the light sensor with a green light filter. 16 photodiode for the light sensor with a blue light filter. And 16 photodiode for light sensor without a color filter. On the use of Color Sensor TCS230 we can choose the color sensor with a filter of what we want to set the configuration data S2 and S3.

Photodiode the TCS230 Color Sensor will issue a magnitude comparable with current levels of primary color of light that happened to him. This current is then converted into pulses with a frequency proportional to the amount of current. TCS230 Color Sensor Output frequency can be made by adjusting the scale of the configuration data S0 and S1 of the selector pins S0 and S1 Color Sensor TCS230.

Thursday, November 13, 2014

Water Sensor Circuit Diagram using IC 555

This is a water sensor /rain alarm circuit diagram; it can be used on motorcycle, car or other device that we want to protect from water, rain.

This is a simple water sensor/rain alarm circuit that makes an alarm when water/rain falls on its sensor. This circuit is based on NE555/LM555 IC and two transistors (Q1&Q2). For transistor Q1- BC547 or BC107 and for Q2- 2N825,BC548 or BC168 can be used in the circuit. This rain detector circuit can be supplied from voltage source of +9V-12V DC. The resistor 470K ohm is a POT/Variable resistor; it is used to adjust the sensitivity of water/rain sensor. Use a 8 ohm,0.5w-1W speaker to hearing better alarm. Less than 8 ohm speaker could be harmful for the IC 555.

This is a simple water sensor/rain alarm circuit that makes an alarm when water/rain falls on its sensor. This circuit is based on NE555/LM555 IC and two transistors (Q1&Q2). For transistor Q1- BC547 or BC107 and for Q2- 2N825,BC548 or BC168 can be used in the circuit. This rain detector circuit can be supplied from voltage source of +9V-12V DC. The resistor 470K ohm is a POT/Variable resistor; it is used to adjust the sensitivity of water/rain sensor. Use a 8 ohm,0.5w-1W speaker to hearing better alarm. Less than 8 ohm speaker could be harmful for the IC 555.

Circuit Diagram of Water Sensor

|

| Fig-1: Water Sensor/Rain alarm circuit diagram |

Water sensor PCB layout:

|

| Fig-2: PCB layout of water sensor |

Heat Sensor Circuit Diagram

This simple heat sensor circuit could senses heat from various electronics device like computer, amplifier etc. and generate warning alarm. It could senses heat from environment also, but here I mention “electronics device” because it is being using mostly in electronic device to protect them from overheat.

Circuit diagram of heat sensor:

|

| Fig-1: Schematic Circuit Diagram Of Heat/Temperature Sensor |

Thermistor, 110 Ohms:

|

| Fig-2: 110 Ohms Thermistor |

As it is a heat sensor circuit, here a thermistor is used as a heat sensor. It is a thermal measurement device and has a variety of usages including temperature sensor/ heat sensor. The thermistor used in this circuit is a NTC (Negative Temperature Coefficient) type thermistor. When temperature increases, its resistance goes decrease. Therefore, NTC thermistor’s resistances are inverse of temperature.

Circuit Description:

You have seen, in this simple circuit diagram of heat sensor, a few number of components is used including a BC548 transistor, a 110 ohms thermistor etc.- BC548: BC548 is a TO-92 type NPN transistor, as its alternative you can use 2N2222, BC238, BC548, BC168, BC183 etc. they all have almost same characteristic.

- 110 Ohms Thermistor: A 110 Ohms thermistor is used to detecting heat. I have told already about it.

- Buzzer: A buzzer is used with +9V and collector of transistor. When the temperature/ heat exceeds a certain level then it make an alarm.

- 4.7V Zener diode: It is used to limit the emitter current of BC548.

- 9V Battery: A 9V battery is used as a single power source.

- R1, R2: A 3.3K 1/4w resistor is used as R1 and 100 ohms 1/4w as R2.

- Switch: Here in this circuit the switch used is a simple SPST switch. You can either use the switch or not, choice is yours. It is not mandatory.

Thursday, October 2, 2014

Gas Sensor Circuit

The proposed gas tester circuit can be simply tested by breathing into the sensor mouth which will confirm its working, since our breath contains CO2 will be immediately detected by this gas sensor circuit.

Its resistance (which in clean air is of the order of 60 k) diminishes as soon as it detects impurities in the air. The CO concentrations normally found in exhaust gases will reduce the resistance to under 3 k. This value will vary somewhat from one sensor to another and, additionally, it is affected by air temperature, humidity, and level of heating voltage.

You will by now understand where the technical limits on measurements with semiconductor gas sensors lie. Before reading further, it may be wise to reread the description of the TCA965 window discriminator. The input voltage to lC2 (pin 8) which is set by P1 rises with increasing air pollution. The thresholds of the discriminator, corresponding to 1 per cent and 4.5 per cent CO contents respectively, are set with P2 and P3. With clean air, the input on pin 8 lies below the lower threshold (pin 7): LED D1 (green) lights because pin 2 of IC2 is logic ’0’in the range of 1.. .4.5 per cent CO, the yellow LED (D2) lights, because the input to pin 8 now lies within the window. When the CO content exceeds 4.5 per cent, red LED D3 lights, because the voltage on pin 8 now lies above the upper threshold (pin 6). So far, so good. All that remains is the setting of the thresholds, but this will be detailed under ’Assembly and calibration.

Preheating indicator

The gas sensor must be preheated every time before it can be used. To save you having to keep looking at the clock, a small auxiliary circuit serves as flashing indicator. After the tester has been switched on, IC3, in conjunction with N3 and N4, generates a low logic level for about three minutes. Gate N2 inverts this signal so that the rectanguIar pulse generator based on Nl drives transistor T1 in rhythm with the pulse rate. After the pre—heating period has lapsed, the output of N3 goes high and the rectangular-pulse generator is inhibited. As the base of Tl is then permanently at high logic level, the LEDs light continuously instead of flash. The pre-heating period is determined by R7 and C4, while the flashing frequency depends on the values of R6 and C3.

Its resistance (which in clean air is of the order of 60 k) diminishes as soon as it detects impurities in the air. The CO concentrations normally found in exhaust gases will reduce the resistance to under 3 k. This value will vary somewhat from one sensor to another and, additionally, it is affected by air temperature, humidity, and level of heating voltage.

You will by now understand where the technical limits on measurements with semiconductor gas sensors lie. Before reading further, it may be wise to reread the description of the TCA965 window discriminator. The input voltage to lC2 (pin 8) which is set by P1 rises with increasing air pollution. The thresholds of the discriminator, corresponding to 1 per cent and 4.5 per cent CO contents respectively, are set with P2 and P3. With clean air, the input on pin 8 lies below the lower threshold (pin 7): LED D1 (green) lights because pin 2 of IC2 is logic ’0’in the range of 1.. .4.5 per cent CO, the yellow LED (D2) lights, because the input to pin 8 now lies within the window. When the CO content exceeds 4.5 per cent, red LED D3 lights, because the voltage on pin 8 now lies above the upper threshold (pin 6). So far, so good. All that remains is the setting of the thresholds, but this will be detailed under ’Assembly and calibration.

Preheating indicator

The gas sensor must be preheated every time before it can be used. To save you having to keep looking at the clock, a small auxiliary circuit serves as flashing indicator. After the tester has been switched on, IC3, in conjunction with N3 and N4, generates a low logic level for about three minutes. Gate N2 inverts this signal so that the rectanguIar pulse generator based on Nl drives transistor T1 in rhythm with the pulse rate. After the pre—heating period has lapsed, the output of N3 goes high and the rectangular-pulse generator is inhibited. As the base of Tl is then permanently at high logic level, the LEDs light continuously instead of flash. The pre-heating period is determined by R7 and C4, while the flashing frequency depends on the values of R6 and C3.

Wednesday, August 27, 2014

Heat Sensor Fire Detector Pyroelectric

These sensors form of Lithium Tantalate pyroelectric parallel opposed dual element high gain detector with integrated analog signal processing. These sensors can detect heat changes from -40 to +70 degrees Celsius without change siginfikan of noise and sensitivity.

To use heat sensor pyroelectric detectors Eltec E442-3, it can take a kind of cone is covered with a fresnel lens to focus the direction of the infrared ray IR. Heat sensors then pyroelectric detectors Eltec E442-3 inserted into the cone is then connected to the microcontroller. Analog output value signals which when detects heat, the sensor will cause a drastic change in output voltage.

Labels:

detector,

fire,

heat,

pyroelectric,

sensor

Subscribe to:

Posts (Atom)